Home

-

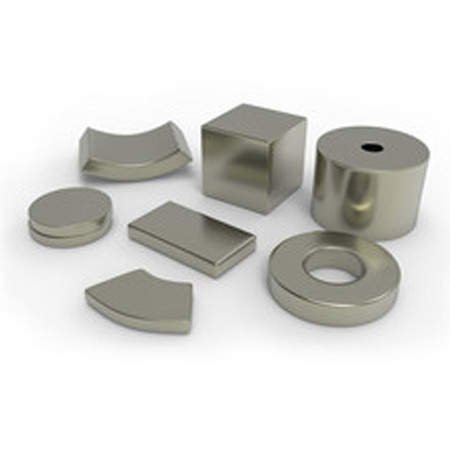

Neodymium Magnets

The neodymium magnet is a type of permanent magnet that is characterized by having a high magnetic force in relation to its size. These magnets are made from an alloy of neodymium, iron and boron and are known for their great ability to retain their magnetic force over the long term.

Neodymium magnets are used in a wide variety of applications, such as computer hard drives, electric motors, speakers, magnetic toys, and more. Due to their high magnetic force, they must be handled with care, as they can cause damage to electronic devices or trap metal objects in their environment.

-

Ferrite Magnets

Ferrite magnets are resistant to many chemical substances, such as solvents, bleaches and fluorhydric acid. Ferrite magnets are quality, economical components that can be found in applications as diverse as automation, control, measurement and others. Ferrite magnets can be isotropic or anisotropic: for anisotropic qualities, the particles are aligned in a single direction, obtaining better magnetic characteristics.

-

Electromagnets

An electromagnet is a type of temporary magnet that is created through the use of an electrical current. It consists of a coil of conducting wire that is wound around a core of iron or other magnetic material. When an electric current is passed through the coil, a magnetic field is created around the core, causing the core to become temporarily magnetized.

The strength of the magnetic field generated by an electromagnet depends on several factors, including the number of turns in the coil, the intensity of the electric current, and the magnetic permeability of the core.

The main sectors of application are:

- Safety and transport: closing devices, automatic doors or fire doors.

- Lifts and elevators: sensors, stairways, ramps or signing and transport equipment.

- Packing and packaging: labelling and packaging machinery or automatic dispensers.

- Medicine: radiology, dialysis, dispensing and artificial respiration equipment.

- Robotics and machinery: industrial robots, motors, presses, domestic appliances, textile machinery and industrial furnaces.

-

Magnetic Separators

Industrial separation systems are used to protect machinery in production processes in different industries, including food, recycling, ceramics, pharmaceuticals or mining, among others.

What are magnetic separators?

Magnetic separators are equipment used to separate ferrous materials (containing iron) from non-ferrous materials, through magnetic attraction. This equipment is used in the industry for the separation and purification of minerals, food, chemical products, plastics, among other materials.

There are different types of magnetic separators, depending on their design and specific application. Some examples are:

- Magnetic pulley separators: used for the continuous separation of ferrous materials on a conveyor belt.

- Magnetic drum separators: used for the separation of ferrous materials from liquids or powdered materials.

- Magnetic plate separators: used for the separation of ferrous materials from liquids or powder materials through magnetic plates.

- Magnetic grid separators: used for the separation of ferrous materials into granular materials.

Magnetic separators are a valuable tool in the industry, as they allow efficient and precise separation of ferrous and non-ferrous materials, thus reducing the amount of waste and increasing the quality of the final product.

-

Alnico Magnets

AlNiCo magnets are permanent magnets made from an alloy of aluminum, nickel, and cobalt, along with iron and other elements. They are known for their high resistance to heat and their ability to maintain a stable magnetic field under extreme conditions.

These magnets are used in a variety of applications, such as motors, generators, speakers, sensors, and laboratory equipment, among others. They are also very popular in the music industry, especially electric guitars, for producing a unique sound.

AlNiCo magnets have a high resistance to corrosion and can work at very high temperatures, which makes them ideal for use in hostile environments. They also have high thermal and magnetic stability, which means that their magnetic strength will not decrease over time, even when subjected to high temperatures.

-

Samarium Magnets

Samarium is a chemical element used to make high-energy permanent magnets, known as samarium-cobalt magnets. These magnets are very powerful and resistant to demagnetization, which makes them ideal for industrial applications such as electric motors, generators, speakers, among others.

Samarium magnets are very expensive because samarium is a rare element and difficult to obtain in large quantities. In addition, the manufacturing process for these magnets is complex and requires high temperatures and intense magnetic fields.

Despite their high quality, samarium magnets also have some limitations, such as their brittleness and susceptibility to corrosion. For this reason, coatings and other protection techniques are used to prolong its useful life and ensure maximum performance.

-

Magnetic Tape

The IMA magnetic tape easily adheres to any metal surface, is very flexible and stays magnetized permanently. We can supply this material in different finishes: natural, with adhesive, in rolls or sheets of different thickness, length and width and with white vinyl coating resistant to water, alcohol, sodium carbonate and other agents.

The magnetic labels are supplied with a white cardboard and a transparent plastic. They are versatile and suitable for the organization of products in warehouses or supermarkets. The magnetic profiles are designed for the closing of screens, sliding doors, and mobile partitions, among others. They are available in different colors. All our magnetic tapes can be used both outdoors and indoors in signs, advertising texts, ski-carriers, advertising for vehicles, etc.

Magnetic tape CM1 isotropic: Magnetized multipolar on one side, offers adequate clamping force for a wide range of applications.

Magnetic tape CM2 anisotropic: Thanks to the orientation of its magnetic particles, this material has a greater force of attraction. It is magnetized by one or two faces, which makes it perfect for countless applications.

-

Magnetic Closures

Magnetic latches, also known as magnetic snap latches, are locking systems that use magnets to hold doors, windows, and other objects closed. They are composed of two parts: a magnetic plate that is placed on the door or window, and a metallic component that is placed on the frame or on the adjacent structure.

When the door or window is closed, the magnets attract each other and hold the door shut. To open the door, a sufficient force is exerted to separate the magnets, allowing the door to open easily.

Magnetic latches are commonly used in applications where a secure lock is required, but without the need for a complete locking system. For example, they can be used on cabinets, drawers, furniture and other objects that require a secure but easy-to-open closure. They can also be used on larger applications such as exterior doors, but in these cases it is important to ensure that the magnetic closure is strong enough to provide adequate security.

It is important to note that magnetic latches are not suitable for all security applications, as they do not offer the same protection as more robust locking systems. It is also important to ensure that the magnets are positioned correctly to prevent the door or window from being accidentally opened.

We have three types of magnetic closures: locking magnets, adjustable magnets and recessed magnets.

-

Magnetic Accessories

Telescopic magnets and magnetic set squares and brooms for work in different sectors.

-

Office Magnets

TYPES OF MAGNETS FOR OFFICE:

Magnetic envelopes: Plastic bags with a magnetized face and a transparent face that allows precise signaling. They are applied on any metal surface and applied in warehouses, factories or commercial areas.Steel-impregnated cardboard: this type of printable cardboard, together with magnetic tape, is suitable for educational games, notice boards and advertising. It can easily be printed and is finished in white on both sides.

Magnetic paper: white for ink-jet printers, on the back it has a thin magnetic layer so it can be printed easily and cleanly. It can be placed on any metal surface and is used for photos, puzzles, images and drawings. It is sold in packets of 10 units.

Magnetic envelopes: plastic bags with one magnetised face and one transparent face, allowing accurate signing. They can be applied to any metal surface and are used in warehouses, factories or shopping areas.

-

DISCOUNTS%